Particle Size Distribution in Concentrated Slurries

Acoustic Spectroscopy

The main distinction of Acoustics for characterizing the particle size distribution is ability to treat concentrated systems as is, when no dilution involved. This method is described in the International Standard ISO 20998-1:2006 “Measurement and characterization of particles by acoustic methods — Part 1: Concepts and procedures in ultrasonic attenuation spectroscopy”

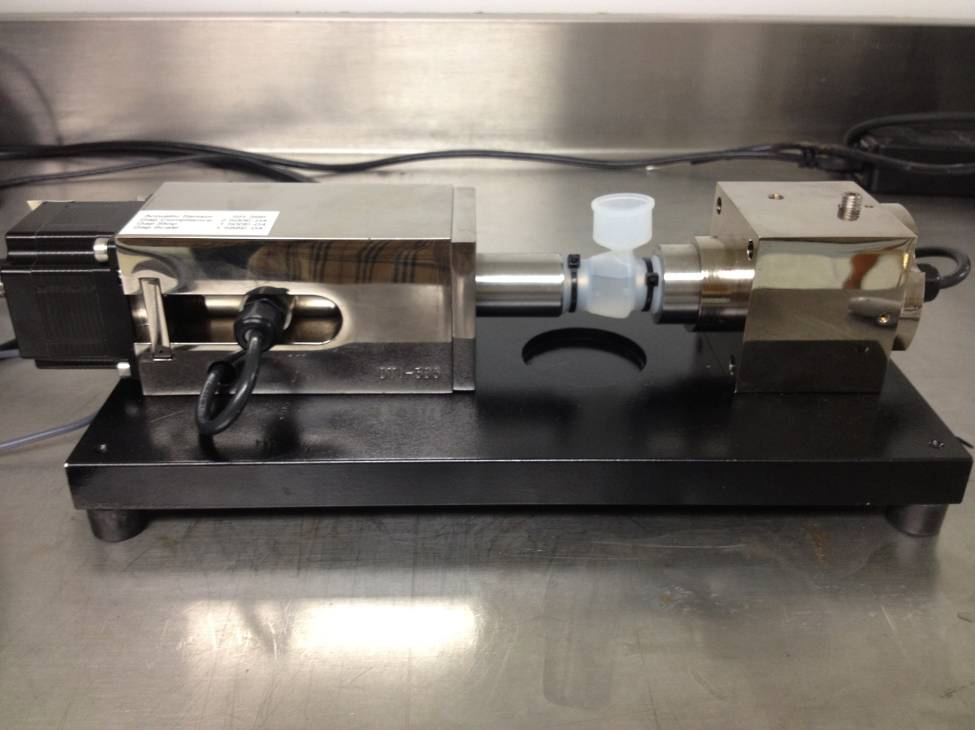

Instruments models

There are four models having this capability: DT-1202 and DT-1210 (size and zeta potential) and DT-100 and DT-110 (size only). Models DT-1210 and DT-110 have disposable sample cell when sample volume is under 5 ml, as shown on the picture below:

Particle size range is from 1 nm up to 1 mm. Generally, particles content must be above 1 % with practically no upper limit.

Ability of Acoustic spectroscopy for characterizing concentrated dispersions and emulsions with no dilution and no sample preparation is critical when dilution affects particle size distribution. In addition, this method works for structured dispersions. Structure contributes to ultrasound attenuation by itself, however, this contribution can be subtracted using appropriate existing theory (see Newsletter #8). Acoustic spectroscopy could also resolve particle size distributions of different particles species in mixed dispersions, assuming that they have different densities (see Newsletter #6).

This method can be used for continuous monitoring of particle size during milling (see Newsletter #18), crystallization, and other industrial processes. One of the most important applications is particle sizing of nano-dispersions and other nano-particulates. Acoustics can monitor presence of nanoparticles with precision of 1%, (see Newsletter #21). Large particles mask nanoparticles when study employs other methods.

Accuracy test for nano-particles.

The paper “Particle sizing and zeta potential of silica Koestrosol (Basis for Certified reference material ERM-FD100 for nano-particles) by Acoustics and Electroacoustics”, Part.Part. Syst. Charact., 27, pp.165-171 (2012) presents results of such test. Here is the Abstract of this paper:

“….Precipitated silica Koestrosol 1530 is the basis for the recently adopted certified reference material ERM-FD100 used for nanotechnology. A similar reference material based on another precipitated silica (silica LudoxTM) has been used for testing ultrasound-based instruments for particle sizing and zeta potential in concentrated dispersions and emulsions for the past two decades. In this study we test silica Koestrosol as a potential replacement for the silica LudoxTM since the latter has not been certified.

The measurements were performed using ultrasound-based instruments, which were suitable for concentrated systems. Two laboratories (USA and Germany) with 3 different instruments were involved. Samples mass fraction was 5%. The statistically averaged mass-based median particle size was found to be 22.4 ±0.5 nm, which is within range of certified values obtained for more diluted samples.”

Accuracy test for micron size particles.

Accuracy test for micron size particles employs a well-known standard Silica Quartz BCR-70. Results are published in our book . Table below presents median particle sizes for several materials with known and reported particle size:

| Sample Material | Median Size (manufacturer data), microns | Median Size (acoustics), microns |

|---|---|---|

| Silica Ludox TM | 0.022 | 0.028 |

| Silica Geltech 1.5 | 1.5 | 1.55 |

| Silica Geltech 0.5 | 0.5 | 0.53 |

| Silica quartz BCR 70 | 2.9 | 2.85 |

| Silica Cabot SS25 | 0.1 | 0.087 |

| Rutile Dupont R746 | 0.3 | 0.31 |

| Alumina Sumitiomo AKP-15 | 0.7 | 0.67 |

| Alumina Sumitomo AKP-30 | 0.3 | 0.33 |

| Zirconia TOSO TZ-3YS | 0.3 | 0.34 |

| Silicon Nitride Ube E-10 | 0.5 | 0.47 |

Independence of the particle size on the weight fraction of solids.

When comparing our instrument with competing technologies / instruments claiming the same functionality, PLEASE be aware of necessity of having verification tests. Evidently, the equilibrium dilution test is the most appropriate for characterizing concentrated systems. The tested instrument should provide the same value of the particle size and zeta potential while measuring various volume fraction of the same concentrated system, IF dilution performed with the equilibrium supernate. Consequently, failure to provide such tests from the highest to the lowest limit of the claimed concentration range, discards particular instrument for the planned application.

International Standard ISO 13099-1 published in 2012 stresses importance of the equilibrium dilution test while selecting method appropraite for particular samples.

We conducted such tests with variety of dispersions. Consequently, our book Dukhin, A.S. and Goetz, J.P. “Characterization of Liquids, Nano- and Micro-particulates, and Porous Bodies using Ultrasound”, Edition 3, Elsevier, 571 pages, 765 references, (2017) presents such results for concentrated TiO2 at 45.9% vl and Silica Ludox TM at 31.2% vl.